UNIVERSAL.

UNIVERSAL.

THE BENEFITS OF IIoT FOR INDUSTRIAL EQUIPMENT SERVICE COMPANIES

Ever daydream about viewing, controlling and updating thousands of machines located across several continents from one simple dashboard? IIoT digitalization and smart data processing platforms have already taken this beyond the realm of the imaginary and into the possible. Smart-servicing and monitoring IIoT solutions start with apps where, through one or two simple settings, small crews of workers can be called to action and go all the way up to systems that monitor and manage a virtually unlimited number of large-scale machines in multiple locations. The benefits are equally scalable, and include less unplanned downtime, increased machine availability, decreased labor costs and improved work safety. Significantly, predictive maintenance can quickly translate into savings of between 8-12% costs over scheduled or preventative maintenance.

REAL

VISION.

CONDITION MONITORING WITH IoT

Condition monitoring refers to inbuilt or retrofitted devices that monitor machine parameters and help to detect faults at an early stage or before they even appear. IIoT sensors, the cogs in the condition monitoring machine, can be used to measure anything from machine temperature to movement to adverse chemical reactions. Other servicing contracts may involve counting the number of people entering a room or calculating the air pressure in heating or AC systems. The readings are sent to the cloud, where an AI-backed middleware platform like relayr’s sorts the data and creates alerts or visualizes patterns on multiple devices carried or used by the relative monitoring or maintenance crews.

REAL

VISION.

PREDICTION.

PREDICTION.

DIGITAL TWIN

The key to predictive maintenance systems and asset monitoring, and the fastest growing IIoT application for industrial manufacturers, digital twin technologies create and visualize perfectly synchronized doppelgangers for machines or processes. Advancements in technology means these models are no longer simulations of the original objects, but true twins as they can also self-optimize according to real-time updates from their ‘partner’. Twin modeling not only indicates faulty parts or sends alerts to signal a current or coming malfunctions, it is also increasingly used to test planned software updates or changes to complex digitalized systems.

EFFICIENT

FUTURE.

BUSINESS OUTCOMES FOR EQUIPMENT

SERVICE COMPANIES

According to the 2018 Gartner IIoT report, digital twin technologies will be implemented by half of all industrial companies by 2021. This is because business outcomes for predictive maintenance using digital twin technology can be significant, with an average efficiency gain of around 10%. Other significant outcomes include better data to aid future product development and improvement and more efficient processes on future lines. It also reduces material wastage and can make considerable time-saving in areas such as model building, planning, reporting and problem solving.

EFFICIENT

FUTURE.

SUCCESS.

SUCCESS.

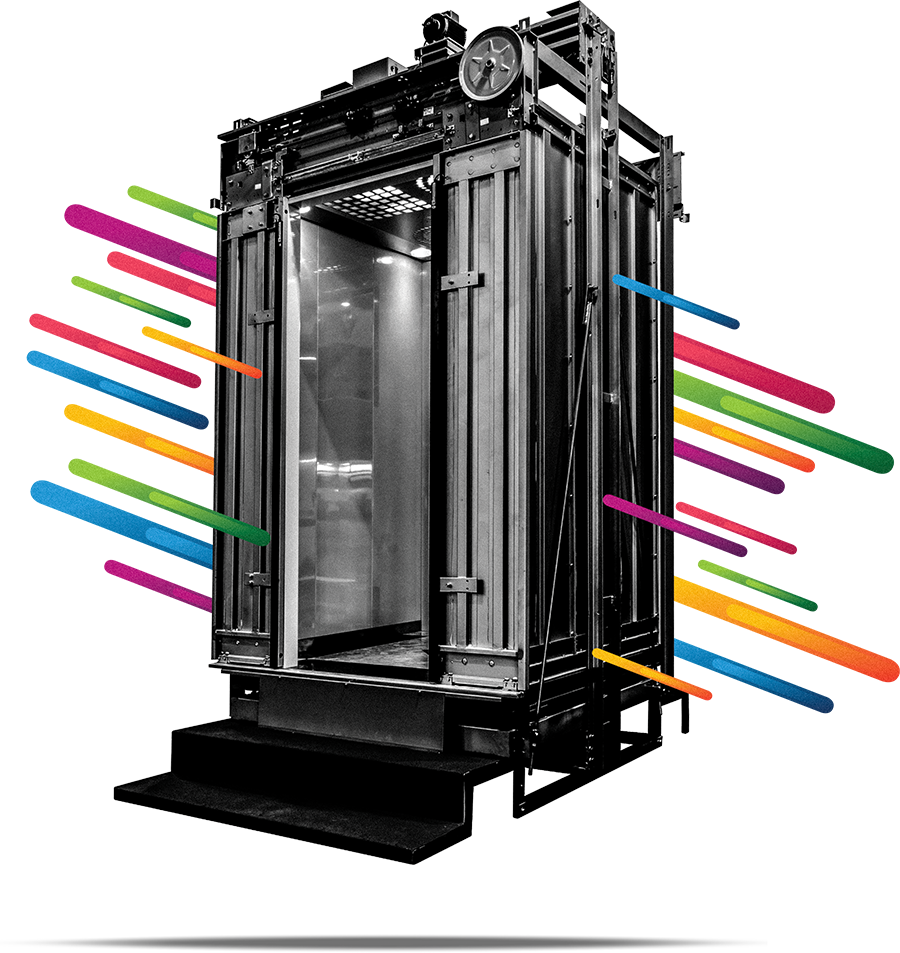

USE CASE: ELEVATOR SERVICE INDUSTRY

Elevator or lift maintenance provides a huge opportunity in IIoT servicing solutions. With hundreds of thousands of models and units operating in different conditions and in different locations, the benefits of being able to identify problems and necessary maintenance issues in advance are clear.

Relayr worked with a leading German elevator provider to improve their servicing efficiency and to reduce costs. The company has elevators at around 100,000 locations across Germany to which it provides lift management, elevator service and maintenance 24/7. Relayr had sensors retrofitted to selected elevators during scheduled maintenance. The sensors sent data to relayr’s platform, which in turn visualized digital twin models of the elevator fleet and provided real-time monitoring on individual and aggregate levels. The results were impressive, if not astounding. The company can now offer automated compliance monitoring on its elevators, which adds new revenue each year. Digital twin technologies, meanwhile, allow savings of up to 500 dollars annually per elevator as maintenance and service teams know exactly when and where to go.

LET'S TALK